Our Infrastructure

PRESS SHOP

Mass production of sheet metal components is incomplete without a press shop.

In press shop we have 15 power press machines and 2 fine blanking machine which have 160T and 250T capacity

SHOP FLOOR

In our shop floor we have

In our shop floor we have,

- Centre less grinding – 4 m/cs,

- Centre lathe -6 m/cs,

- Auto lathe – 4 m/cs

- Welding facilities- Spot welding,Arc welding,C02 welding

- Deckal Maho-vertical machining centre(VMC)

- Hydraulic shearing m/c up to 6.0mm thick,

- Grind master conveyer belt linishing

- spray painting,

- Vibro process

- Component Straightener for better flatness accuracy upto 0,3 mm

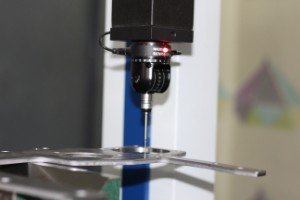

TOOL ROOM

To achieve Accurate Toolings we make use of the best available technologies like Spark Erosion , Laser Cut,Wire EDM and many more processes Vaccum Hardening Special coatings of Dies . We develop our tools with high accuracy and reliability with minimum lead time. We design tools using latest latest Siemens Software. In addition Our Tool Room is manned by Qualified Tool and Die makers /Fitters and also equipped with multiple lathes, grinding machines and drilling machines